CLARKSVILLE, TN – Ross Rodriguez knew the statistics were daunting: by 2050, the world is projected to produce about 12,000 megatons of plastic pollution, much of it from manufacturing used in everything from aerospace parts to automobiles.

But armed with natural plant fibers, chemical treatments, and 10 weeks at Oak Ridge National Laboratory, the Austin Peay State University engineering physics student set out to tackle this environmental challenge head-on.

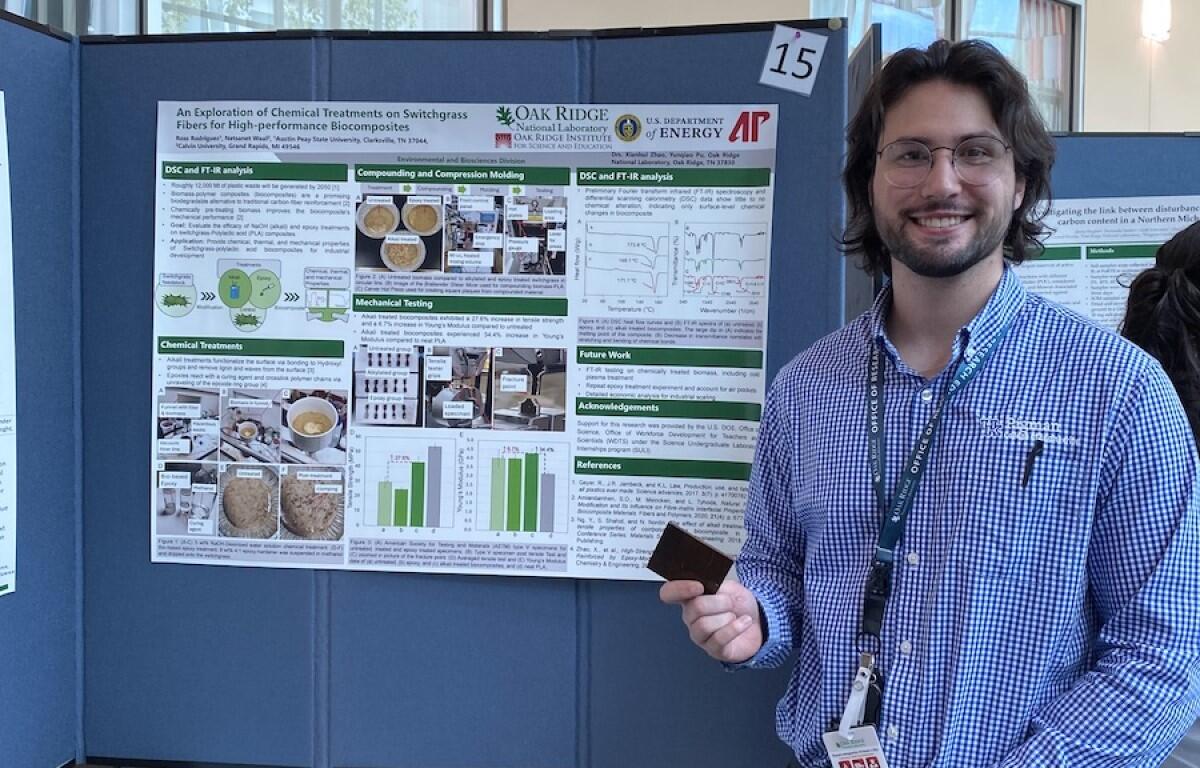

Rodriguez was one of the first students from Austin Peay’s engineering physics program to earn a coveted Science Undergraduate Laboratory Internship (SULI) through the Department of Energy — a highly competitive program that required three essays, multiple letters of recommendation, and what Rodriguez describes as “a billion questions” on the application.

“I didn’t know that Steven and I were the first ones to get it,” Rodriguez said, referring to fellow Austin Peay student Steven Warth, who also earned a SULI position. “It’s a competitive program, and the whole application process took me probably a week to fill everything out.”

From theory to practice

Rodriguez’s project focused on developing biodegradable composite materials that could replace traditional carbon fiber reinforcements. The challenge: polymers like PLA (polylactic acid) are flexible but not strong, while carbon fiber reinforcements provide strength but aren’t biodegradable.

“We’re utilizing the fiber aspect, the reinforcing aspect from plant fibers and incorporating them into polymer matrices as a substitute for carbon fiber,” Rodriguez said. “You get that increase in rigidity that you need for high-performance composites, but you also get that sustainability aspect because it makes it biodegradable.”

His research used biomass fibers from sources like tree bark and various grasses, whose components provide natural strength. The resulting composites are not only biodegradable but also cheaper, lighter, and better suited for aerospace applications than traditional alternatives.

The trade-off, however, is brittleness. While the bio-composites are stronger and more rigid, they lose some flexibility and break sooner than traditional polymers.

Solving adhesion problem

Much of Rodriguez’s work focused on chemical treatments to improve how plant fibers bond with polymer matrices. The problem: natural fibers have waxy coatings that cause them to slip out of the polymer matrix during stress, leading to premature failure.

“Most of that is due to the fact that the fibers dislodge themselves when they’re being pulled apart before the polymer or the fiber itself breaks,” Rodriguez said. “So it’s bad adhesion.”

His solution involved surface treatments using sodium hydroxide to wash and abrade fiber surfaces, removing waxes and impurities. The process is then neutralized with acetic acid to bring pH levels back to safe, environmentally-friendly levels.

Rodriguez also experimented with bio-based epoxy treatments that act as a biodegradable glue between fibers and polymers, helping prevent slippage while maintaining environmental sustainability. With all deliverables due at the end of the eighth week of the program, Rodriguez was on a strict timeline to reach his conclusions.

The work was largely independent, with weekly mentor meetings and collaboration with other researchers on adjacent projects. Rodriguez worked under two mentors due to space constraints, using lab facilities in one building while reporting to his original mentor in another.

“I was very independent; it was very hands-off with my mentors,” Rodriguez said. “A lot of it is on the student, which I actually really appreciated because a lot of times, especially in industry work, it’s all down to you to get your work done.”